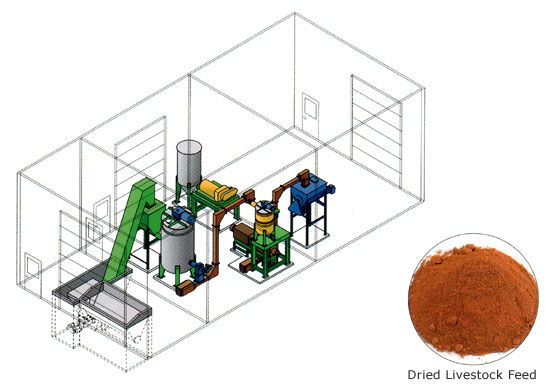

Raw Garbage Boil & Dry for Livestock Feed Plant

A non-polluting system for the production of livestock feed (without waste water or hazardous odours) becomes a reality at last.

After the boil & dry processing, the material is subjected to a high-temperature heat sterilizing, and this is followed by the oil/fat extracting process, which reduces the fat content to 10%, thus rendering it a high quality and safe product. During the boiling process, a waste steam is produced which contains a strong smell, so this is conducted to the Teinenpi Deodorizing Apparatus. In the Teinenpi, the waste gas is treated through an oxidizing pyrolysis process at high temperature and is thus converted into a non-polluting gas which can be safely emitted into the atmosphere. By this method, no waste water is produced. It is quite clear that the expensive waste water treatment facilities required by traditional plants are not needed in the case of the Okadora plant.

Solid Picture

Flow Chart