Full Range of OKADORA System at a Glance

Waste Material Becomes A Resource For 21st Century

Traditionally, waste material was dealt with as no longer having any use, and treated as material to be disposed of. But today, it is time to recycle waste material under the proper management. Okadora will meet global needs by with the provision of original technology.

Drying Raw Garbage, Leftover Food, and Waste Food.

Outstanding processing capability without the need to sort out foreign objects.

Drying Contaminated Mud and Sludge.

Any form of sludge from liquid to solid can be handled at any desired rate of moisture content !

Drying Raw Garbage for Production of Livestock Feed.

Large quantities of raw garbage can be processed into livestock feed without producing any waste water, odors or broth.

Fish Meal Plant.

A first in the industry ! The OKADORA Fish Meal Plant processes ingredients without producing any broth, waste water or hazardous smells.

Livestock Feed Production System for Meat & Bone Meal.

Production of high quality livestock feed by processing meat and bone meal.

Direct Carbonizing of Sludge and Livestock Excreta.

Super Speed Carbonizing processes livestock excreta into a non-pollutant without waste water or hazardous smells.

Drying and Carbonizing Process for Waste Material with Moisture Content using Non-Waste Water and Non-Smell Treatment. (Intermediary Management)

In the same apparatus it is possible to treat septic matter, liquid sludge, dehydrated sludge, and chemical waste liquids without waste water or odors.

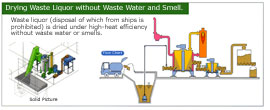

Drying Waste Liquor without Waste Water and Smell.

Waste liquor (disposal of which from ships is prohibited) is dried under high-heat efficiency without waste water or smells.

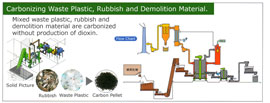

Carbonizing Waste Plastic, Rubbish and Demolition Material.

Mixed waste plastic, rubbish and demolition material are carbonized without production of dioxin.

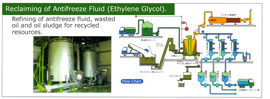

Reclaiming of Antifreeze Fluid (Ethylene Glycol).

Refining of antifreeze fluid, wasted oil and oil sludge for recycled resources.

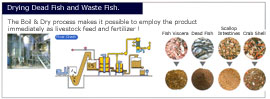

Drying Dead Fish and WasteFish.

The Boil & Dry process makes it possible to employ the product immediately as livestock feed and fertilizer !

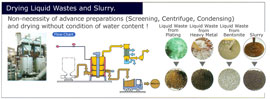

Drying Liquid Wastes and Slurry.

Non-necessity of advance preparations (Screening, Centrifuge, Condensing) and drying without condition of water content !

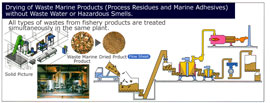

Drying of Waste Marine Products (Process Residues and Marine Adhesives) without Waste Water or Hazardous Smells.

All types of wastes from fishery products are treated simultaneously in the same plant.

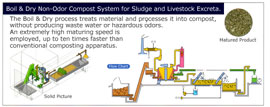

Boil & Dry Non-Odor Compost System for Sludge and Livestock Excreta.

The Boil & Dry process treats material and processes it into compost, without producing waste water or hazardous odors. An extremely high maturing speed is employed, up to ten times faster than conventional composting apparatus.

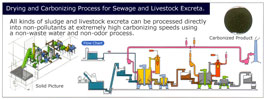

Drying and Carbonizing Process for Sewage and Livestock Excreta.

All kinds of sludge and livestock excreta can be processed directly into non-pollutants at extremely high carbonizing speeds using a non-waste water and non-odor process.

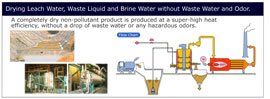

Drying Leach Water, Waste Liquid and Brine Water without Waste Water and Odor.

A completely dry non-pollutant product is produced at a super-high heat efficiency, without a drop of waste water or any hazardous odors.

Carbonizing Medical Waste.

Medical waste, paper napkins and rubbish are directly carbonized simultaneously.

Carbonizing & Oil Production from Used Tires.

Within 60 minutes, used tires will be broken down into oil, carbon and steel without any pollution.