Carbonizing Fusion Gasifying

Power Generation System

The Principle of Carbonizing, Fusion and Gasifying

The gasification furnace is divided into two sections. Carbonized products, gasifying agents and air are supplied to the lower part of the chamber (the combuster). In this stage of the process, the main chemical reactions include a complete and partial combustion reaction of carbon and oxygen , as well as gasification with carbon, carbon dioxide, and steam. The combustion reaction is exothermic, while gasification is endothermic. The high temperature gas of 1,100 degrees C or more is generated by controlling the supply/distribution of carbon and air. Moreover, the ash content in the fuel is harmlessly melted by the high temperature gas, and is discharged in a solid glass-like state.

The high temperature gas from the combustion chamber is moved to the upper section of the gas reformer, and is mixed with the pyrolysis gas generated at the time of carbonization.

Although the pyrolysis gas contains carbon monoxide, hydrogen, methane, steam, tar and pre-dioxin matters in part, the high temperature gas with more than 1,100 degrees C, decomposes a part of the tar, as well as preventing the generation of dioxin. Consequently, a fuel gas with more than 1,000 degrees C kcal/Nm3 is obtained.

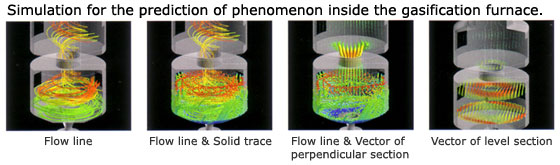

Simulation for the prediction of phenomenon inside the gasification furnace.